Every element of meat storage is just as important as the next and knowing the best practices for storing your produce, whether fresh or frozen, is essential for your business.

This guide looks at the various ways you can ensure your meat is safely stored for higher quality produce, no matter if you’re a caterer, restaurant owner, supermarket or distributor.

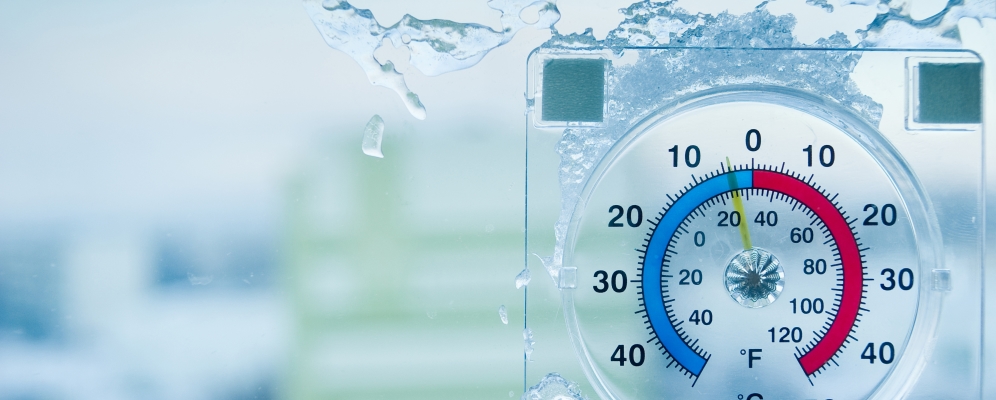

Temperature Requirements

Depending on whether you intend to keep your meat chilled or frozen will depend on the specific temperature requirements for your produce. Legally, a temperature of -18°C is required for all frozen produce but this is the absolute maximum, meaning that temperatures lower than this are the safest option.

For chilled goods, a temperature of 4°C and below is regarded as the ‘safe zone’ for storing chilled meats but much like freezing, colder temperatures may give greater peace of mind. Asides from regulation, lower temperatures also offer other benefits such as extended storage times.

Safe Storage Times for Meat

If using cold storage for freezing, you can extend the life of your fresh meat considerably. This creates a number of benefits such as the ability to expand your stock and the range of products you sell, as well as increasing profitability through a reduction in waste.

The below storage times offer an approximate guideline for a variety of common meats but shelf life can sometimes vary. Improper storage conditions and temperature fluctuations can cut the shelf life of raw meat short, so always check your stock regularly and trust your senses if something doesn’t seem right.

Average Meat Shelf Life when Frozen at Temperatures Below -18°C

Beef – 12 Months

Beef Mince – 6 Months

Lamb – 12 Months

Pork – 8 Months

Veal – 10 Months

Sausage – 6 Months

When storing meat at temperatures of 4°C and below, shelf life drops considerably and this should be taken into account if using cold storage in restaurants or at catering events.

Regular meats, such as beef, pork, lamb and sausages typically last between 3 – 5 days at these temperatures. Minced meats, offal and poultry generally have a slightly shorter shelf life of 3 days maximum.

Again, using your sight and smell are often the best indication of whether a product is safe to consume but sometimes spoilage isn’t as easy to spot. Always stick to the approved sell-by dates and if you can’t be certain that a product is safe to consume then do not serve it or sell it.

Best Practices for Packing and Stocking

Good packaging and stocking techniques go a long way in preserving and protecting the goods that you store and are an important requirement for safe cold storage of meat. All meat should be individually wrapped in tight packaging, free from holes or tears.

It’s important to check packaging for imperfections before moving into cold storage, as leakages can result in cross contamination and meat spoilage, both of which lead to waste and profit loss.

Another effective technique for stocking is the ‘first in first out’ rule for new produce coming in. This is common practice for most businesses working in the food industry nowadays and should be implemented as soon as possible if your business does not already follow this.

If you do already have a similar procedure in place, ensure this is being correctly implemented to minimise waste and improve safety within your cold storage units.

Meat in Ambient Atmospheres

Safe storage of meat starts with safe handling and preparation. This is why it’s important to never re-freeze or re-chill meat if it has been left out at room temperature. It doesn’t take long for meat to reach potentially harmful temperatures where bacteria can develop, making meat potentially unsafe for consumption.

If transferring produce from one cold unit to another, ambient temperature exposure should always be kept to a minimum. Continuously reviewing and improving your operational processes will almost certainly improve the quality of meat in cold storage.

Unless you plan on using meat, it should never be removed from cold storage for a prolonged period of time.

Cold Storage Maintenance

Refrigeration and freezer maintenance is another incredibly important requirement for the safe cold storage of meat. Highly quality units are built to last and rarely come into problems but if the correct maintenance and review procedures aren’t undertaken, you could risk compromising the effectiveness of your cold storage unit.

Some tips for cold storage maintenance:

- Regularly check for temperature fluctuations. If something doesn’t seem right, call an engineer immediately and tackle potential problems before they result in food contamination or food wastage.

- Do not place your cold storage in an area where the fans are likely to be obstructed in any way. This can cause the fan to overheat, damaging your unit and warming the internal temperature.

- Ensure that a regular deep clean is part of your cold storage maintenance routine to reduce the risk of cross contamination and bacterial build up. Cold storage units keep your meat at a safe and consistent temperature but it’s up to you to adhere to the correct safety and hygiene standards.

At CRS Ireland, we offer a wide range of commercial, food-grade cold storage units specifically for use with meat, fish and poultry products. To find out more about how our commercial refrigeration and freezing could improve the safety of your produce, get in contact with a member of the team today.